HYBRID MARINE SYSTEM

HYBRID MARINE SYSTEMS (HMS)

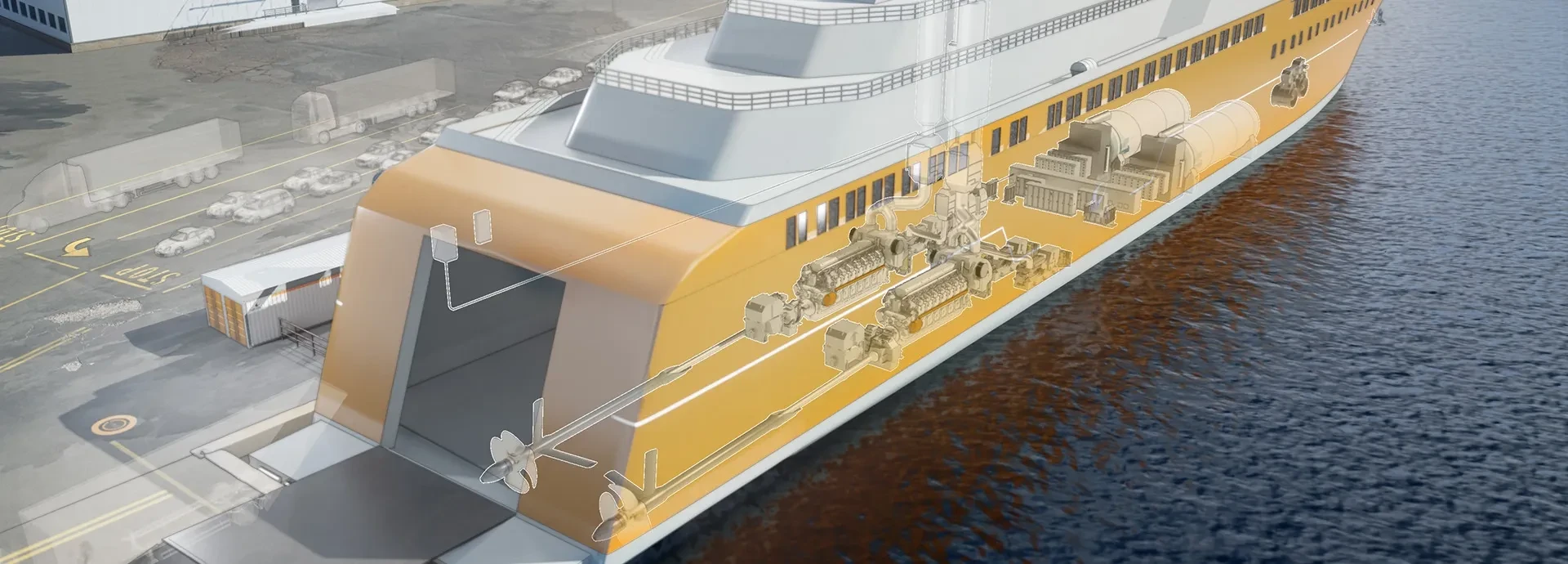

Hybrid propulsion systems for marine applications combine combustion engines with battery power to optimize engine operation while reducing emissions. These are ideal for vessels with flexible operation profiles and running hours with varying power demands.

The new Meridium HMS solutions reduce fuel consumption, greenhouse gas emissions, maintenance costs and noise production, while increasing revenue and technical efficiency.

Benefits at a glance

- Fewer NOx, SOx and CO2 emissions

- Zero emissions when just batteries are used (especially at slow speeds or harbor)

- Increased fuel efficiency

- Silent operation

- Wide range of operation modes

The Meridium HMS is suited for both diesel-mechanical propulsion and diesel-electric propulsion.

Vessels of all kinds can benefit from this hybrid solution, including:

- Ropax ferries

- Ferries

- Shuttle tankers

- Platform supply vessels (PSVs)

- Tugs

- Mini-bulkers

- Bunker vessels

- PCTCs (pure car and truck carriers)

- Fishing boats.

Meridium will configure and set up the hybrid propulsion system according to each vessel’s operating profile.

HYBRID BULKERS

The HMS Module for Bulkers is a compact, containerized solution featuring an energy storage system. For instance, additional energy sources like solar panels can be integrated, allowing the extra energy to be fed into the grid as auxiliary power.

Placing the container on deck saves space and enables installation without the need for drydocking.

This hybrid marine solution can reduce your vessel's emissions by up to 4%. Opting for the HMS Module for Bulkers can help you comply with regulations and ensure a more profitable future for your business.

HYBRID FERRIES

The solution is quiet and decreases emissions, which will please the communities located near ferry ports. Passengers will appreciate the quieter ferry engines and the reduced vibration and smoke.

In fact, the hybrid solution allows the engines to be switched off near the port or on short routes. The ferry will operate quietly and without smoke – and retain its excellent manoeuvring performance. There will also be significant fuel savings and less need for maintenance.

Zero-emission operation – the green mode – includes

- Diesel mechanic propulsion

- Two main propellers

- Stern thrusters

- rapid, wireless charging of the energy storage system

The estimated payback time for such a configuration is only around four years, depending on the price levels of fuel and shore power.

WHICH KIND OF BATTERIES AND FUEL CELLS SHOULD BE USED?

Three types of batteries used in automotive and energy markets are suitable for marine use:

- NMC (Nickel-Mangan-Cobalt)

- LFP (Lithium-Ferro-Phosphat)

- LTO (Lithium-Titan-Oxid)

Meridium experts will select the most suitable type for each vessel application – in the same way they select the other electrical components such as power drives, generators, motors, and transformers.

There is currently one suitable fuel cell type for marine use: the PEM (Proton-Exchange-Membran) fuel cell.

PEM fuel cells are practical for vessels that run on hydrogen fuel. Using a PEM fuel cell together with other alternative fuels will require a reformer, and that will bring the efficiency down to the level of a regular combustion engine, bringing no benefits.

The Solid-Oxide Fuel Cell (SOFC) technology is under development for marine applications. This is a promising technology because it will be able to use alternative fuels like methanol and ammonia.